FDA Action on 3D Printing of Medical Devices at the Point of Care

In the medical device field, manufacturers and regulators are constantly trying to balance the advantages of new and emerging technologies with the complex, and often lengthy, regulatory process to ensure the devices are safe and perform as they are supposed to. This impacts a variety of areas in medical device development, in everything from artificial intelligence to mobile medical devices. This issue has also come to the forefront in 3D printing of medical devices at the point of care (PoC), where the Food and Drug Administration (FDA), the agency that oversees medical devices in the United States, has recently taken steps to address the issue.

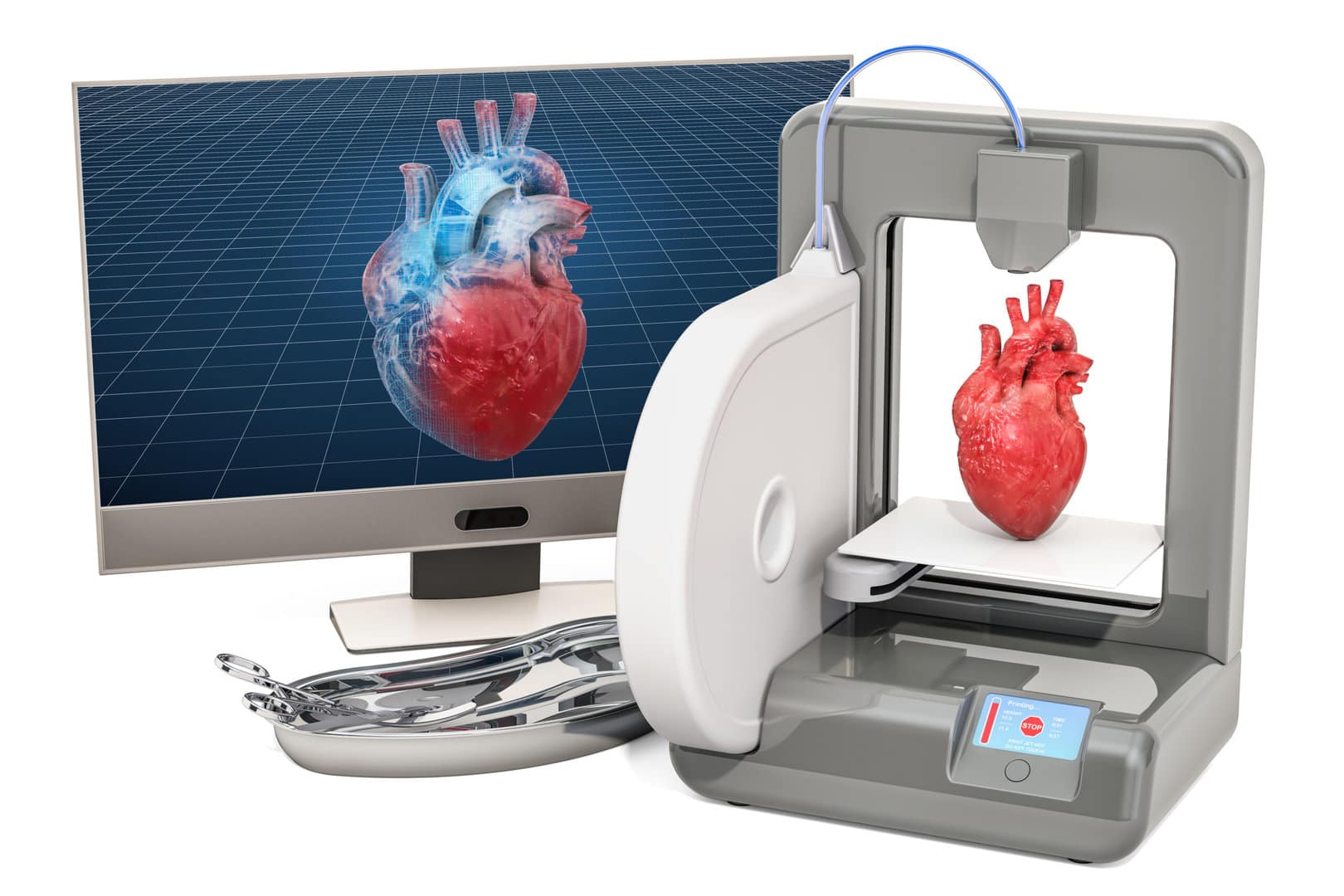

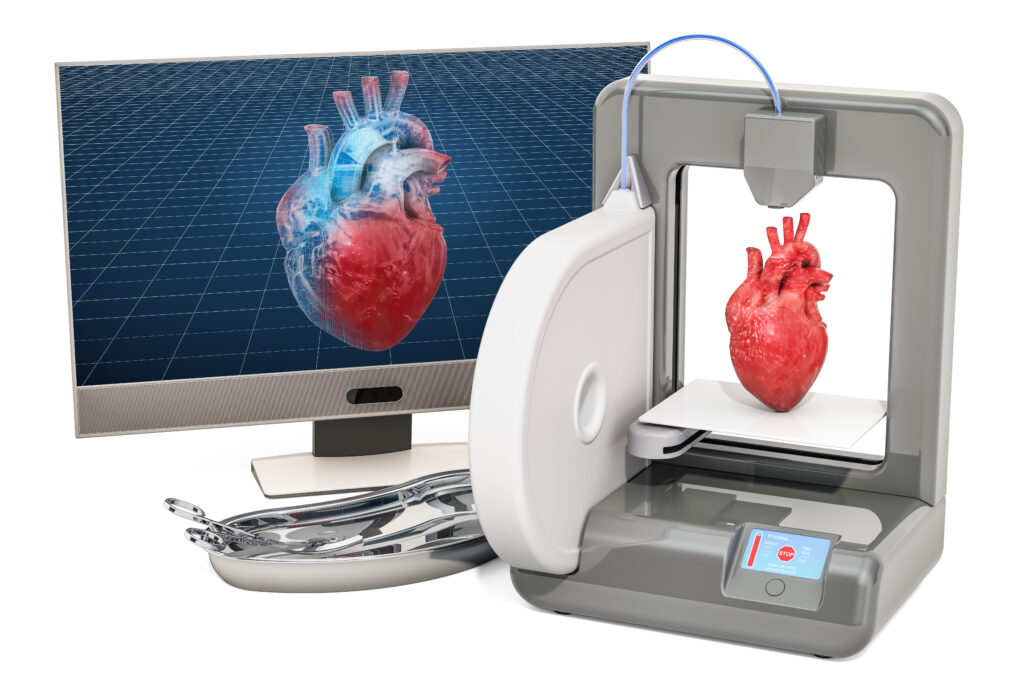

3D Printing and Medical Devices

3D printing in medical equipment offers many advantages for medical professionals and patients. A surgeon could use a 3D-printed replica of a patient to evaluate different surgical techniques. Using 3D printing for medical devices at the point of care means a patient can have a customized medical device in a short period of time. When the COVID-19 pandemic first hit the U.S., the health care industry quickly learned it lacked the proper inventory and safety net to overcome the supply chain disruptions brought on by the public health crisis. During this time, health care providers and facilities utilized 3D printing technology to produce face shields, face mask holders, nasopharyngeal swabs, and ventilator parts during the shortage.

FDA Discussion Paper

The growing potential of 3D printing in medical devices and its use in point of care medical devices, especially in the aftermath of the pandemic outbreak, prompted the FDA to consider how to regulate health care facilities performing 3D printing for medical devices at the point of care. To begin the regulatory process, the FDA released its discussion paper, 3D Printing Medical Devices at the Point of Care, to outline the issue and gather feedback that will inform future guidance and policy related to PoC medical devices and 3D printing.

The FDA’s primary concerns are to ensure:

- The devices are safe and effective to use.

- The devices are subject to the appropriate controls and PoC testing for devices.

- There is an entity responsible for FDA compliance.

- Proper PoC training and capabilities are in place to make sure those responsible for 3D printing at the PoC have the necessary knowledge and expertise.

The FDA is using the discussion paper to solicit feedback on several regulatory approaches, including:

- Continuing a risk-based approach where the agency’s oversight corresponds to the printed device and the printing of the device at the PoC.

- Asserting that the device specification should not change based on the location of where the device is manufactured, no matter if it is a traditional medical device manufacturing facility or using 3D printing for medical devices at the PoC.

- Considering the capability of the health care facility, including their ability, training, oversight, and relevant experience.

- Clarifying responsible parties and setting the expectation that entities understand their responsibilities for the product’s lifecycle.

- Adapting existing controls to create a more streamlined and less complicated approach.

To accomplish this, the FDA outlined three potential regulatory scenarios for 3D printing for medical devices at the point of care. The first relies on the manufacturer of the 3D printer to assume regulatory compliance responsibilities. The second requires the health care facility to partner with a traditional device manufacturer operating at or near the facility that would be responsible for FDA compliance. And the third places the regulatory obligation on the health care facility itself. Since the discussion paper does not provide specific policies at this time, we will continue to monitor its process to be able to provide our clients with the most current advice on point of care devices. One of the benefits of working with Sterling is that we provide both engineering and regulatory support for medical device development. If our medical device design services can help you get your device to market, please contact us.